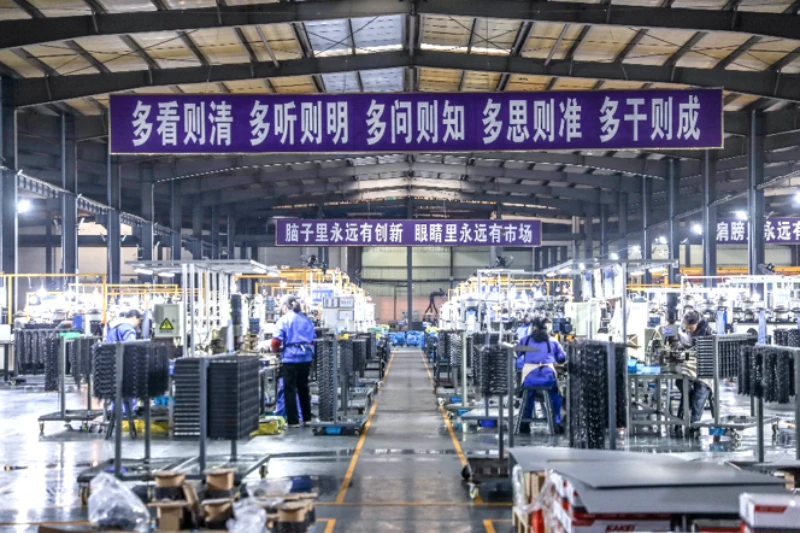

Manufacturing Line

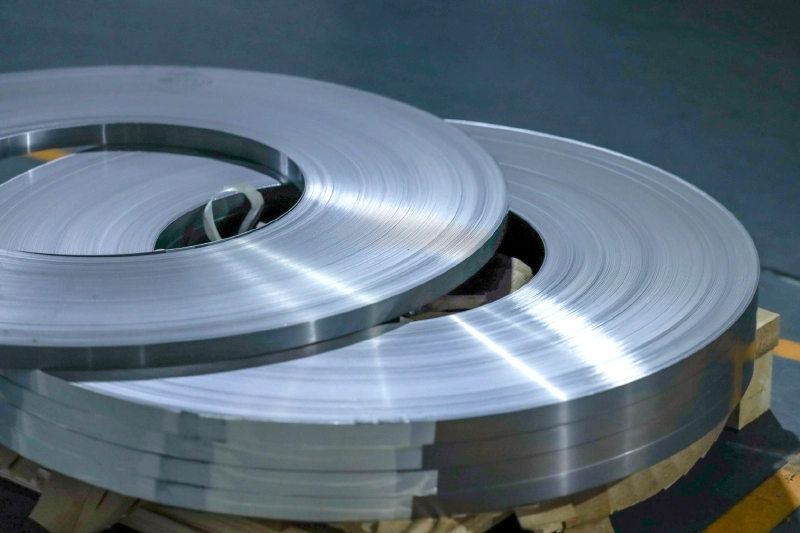

Raw Material Preparation

- Select high-quality alloy steel (e.g.,68CrNiMo, 65Mn and so on) as the base material for chain links, cutters, and rivets, ensuring compliance with material hardness and tensile strength standards.

- Perform pre-processing such as degreasing, derusting, and surface cleaning on raw materials to remove impurities and ensure subsequent processing accuracy.

Component Processing & Forming

- Chain Link Stamping: Use precision stamping dies to punch raw steel plates into chain link blanks (inner links, outer links), controlling dimensional tolerance within ±0.02mm.

- Cutter Machining: Cut cutter blanks by precision die stamping – use customized stamping dies to shape raw steel plates into cutter blanks, ensuring the cutting edge angle (typically 30°-45°) and overall contour meet design requirements. Grind the cutting edge with a precision grinder to achieve a smooth surface and sharp cutting performance; perform heat treatment (quenching + tempering) to enhance hardness and wear resistance.

- Rivet Production: Cold-heading steel wires into rivet blanks, then perform threading and polishing to ensure tight fit with chain link holes.

Assembly Process - Chainsaw

- Assemble inner links, outer links, cutters, and rivets in sequence using automatic assembly equipment: insert rivets through the holes of inner and outer links, then rivet firmly to form a basic chain section.

- Install cutters onto the chain links with positioning jigs, ensuring the cutter projection height is consistent (0.8-1.2mm) to guarantee uniform cutting force.

- Conduct initial tension adjustment to ensure the assembled chain moves flexibly without jamming.

Post-Processing

Surface Treatment: Perform anti-corrosion treatment on the assembled saw chain, such as electroplating (zinc plating, chrome plating) or spray painting, to improve rust resistance and service life.

Assembly Process - Guide Bar

Quality Inspection

Quality Testing:

- Dimensional inspection: Use calipers, micrometers, and coordinate measuring machines to check key dimensions (chain pitch, link thickness, cutter width).

- Visual inspection: Check for defects such as cracks, burrs, or loose rivets, and remove unqualified products.

- Performance testing: Conduct tensile strength tests (minimum tensile strength ≥ 800MPa) and wear resistance tests; simulate actual working conditions to test cutting efficiency and stability.

Packaging & Loading

- Cut the qualified saw chain into specified lengths (e.g., 10ft, 15ft) according to customer orders, and install connecting links for easy on-site assembly.

- Package the saw chain with moisture-proof paper and plastic film, then place it in cartons with shock-absorbing materials to avoid damage during transportation. Label each package with product information (model, length, batch number, production date) and store it in a dry, ventilated warehouse;

- implement batch management to ensure traceability.